English

某一职位:

Home >

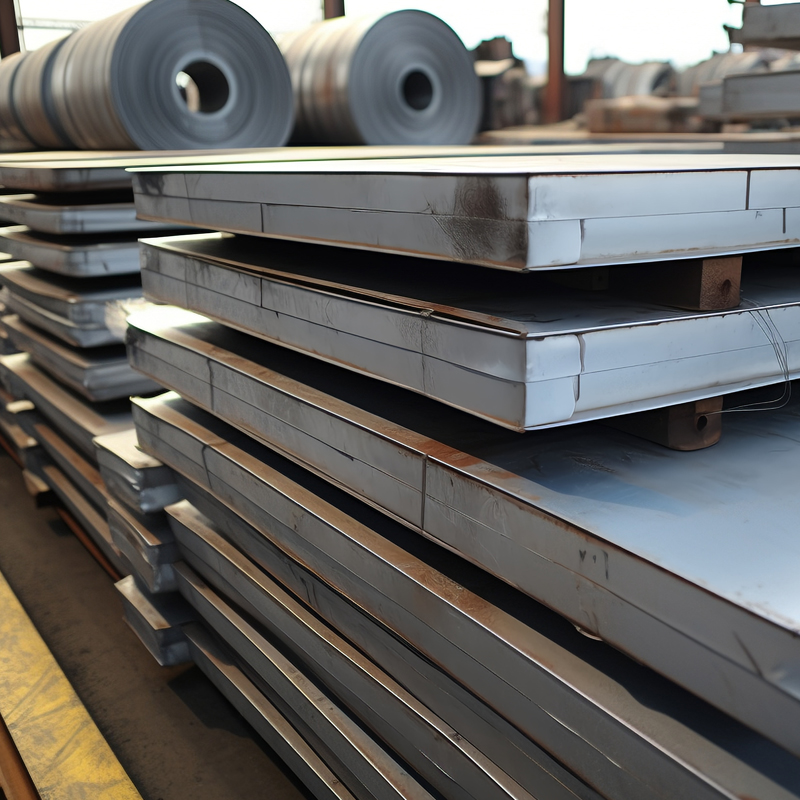

N08028

1/1

N08028

share

Application Areas: Wet Phosphoric Acid Industry: Core application sector. Used in evaporators, heat exchangers, reactors, pumps, valves and piping systems, offering resistance to fluoride, chloride and sulphate impurities in phosphoric acid. Sulphuric Acid Environments: Demonstrates excellent performance in sulphuric acid environments of moderate concentration and temperature, frequently employed in sulphuric acid recovery systems and acid coolers. Oil and Gas: Downhole tools and pipelines in highly corrosive oilfields, particularly those containing hydrogen sulphide, carbon dioxide, and chlorides. Environmental Protection and Flue Gas Desulphurisation: Critical components in high-efficiency flue gas desulphurisation systems, handling flue gases with high sulphur content and complex chemical compositions. Chemical Transport: Tankers for chemical vessels, used to transport highly corrosive chemicals such as phosphoric acid and sulphuric acid.

18651586300

立即预订

企业产品详细情况

Alloy 28 is a super austenitic stainless steel characterised by high chromium and molybdenum content, with added copper and nitrogen. Its chemical composition is meticulously balanced to deliver exceptional corrosion resistance in both strongly oxidising and reducing acidic media, particularly in environments containing halide ions. It serves as a highly cost-effective alternative to numerous expensive nickel-based alloys, such as Hastelloy C-276. Core Characteristics: Outstanding Comprehensive Corrosion Resistance: Demonstrates exceptional resistance to sulphuric acid, phosphoric acid, and their mixed acids, making it a standard material selection for the wet phosphoric acid industry. Exceptional Resistance to Localised Corrosion: Extremely high molybdenum and nitrogen content provides formidable resistance to pitting and crevice corrosion, effectively countering halide ions in acidic media. Superior stress corrosion cracking resistance: Demonstrates significantly higher resistance to stress corrosion cracking than conventional stainless steels in chloride-containing acidic environments. Good weldability and formability: Retains the favourable processing characteristics typical of austenitic stainless steels. High cost-effectiveness: In numerous strong acid applications, its performance rivals that of more expensive nickel-based alloys while offering significantly reduced costs.